Home > Dehumidifying Dryers Series > Honeycomb Rotor Dehumidifier

Home > Dehumidifying Dryers Series > Honeycomb Rotor Dehumidifier

![]()

Characteristics of theHoneycomb Rotor Dehumidifier

1. Steady dew point temperature;

2. No pollution and ensures the quality of the plastics;

3. Change the LICL into the moisture hygroscopic to produce flow;

4. The base material crystallized with the silica gel without thewash-away problems due to the short binding force of the silica powder producedby the immersion wheel.

5. Improve the particle molecular sieve drum and disc dehumidifierdue to the shortness of the powder going into the drying cylinder along with thewind afer the molecular sieve is damaged.

6. Large absorption area and low pressure of loss;

7. Low energy cost and high efficiency;

8. Long service life and washable; Wheel base material forinorganic ceramic fiber, acid and alkali corrosion resistance, and resistanceto high temperature of 1000 in case of a fire happens. For adsorbent crystalforming property may be watered or use solvent to clean it and its performancedoes not decline, its average life expectancy is more than 10 years.

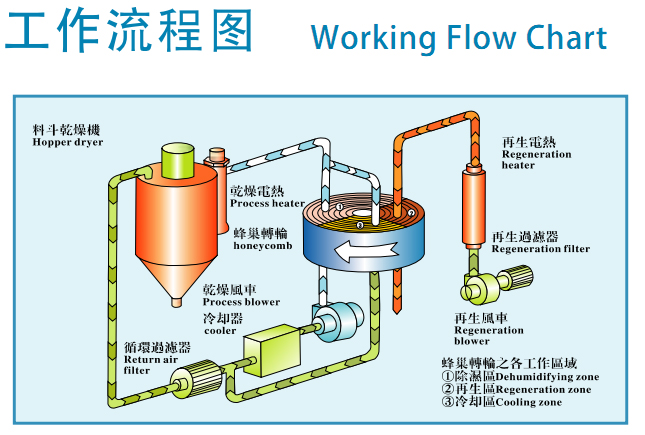

Working Principle

NIASI Honeycomb Rotor Dehumidifier Series’ core component is thehoneycomb dehumidifying rotor which is rotating constantly and slowly. Thisrotor is devided into three areas: dehumidifying area, regenerating area and the cooling area. When the humid air needs to be dehumidified, it enters into the dehumidifying area,the moisture in the humid air is absorbed by the silica gel in the wheel and gets dry. The dried air is sent to the users through the blower. As the moisture is saturated gradually,under the drive of the regulating motor, it slowly goes into the regenerating area and starts the regenerating process. When the regenerating air reaches at 180℃ after heating,it will be reserved blown into the regenerating area in order to eject the water molecules inside the wheel and is blown out by the blower and finishes the regenerating process.After regeneration, its moisture absorption ability is recovered. Under the drive of the regulating motor,it enters into the cooling area slowly. After dry-air cooling,it enters into the dehumidifying area to dehumidify.The above dehumidifying,drying and cooling process happen at the same time. The air is dried and the wheel is regenerating constantly. Such a cycle ensures the steady working condition of the dehumidifier and completely solves the shortage of the dew point fluctuation of other dehumidifiers and high energy consumption.

Technical Parameters:

Model/ND | 50 | 80 | 120 | 150 | 200 | 300 | 400 | 500 | 700 | 1000 | 1500 | |

| Drying capacity | M3/hr | 50 | 80 | 120 | 150 | 200 | 300 | 400 | 500 | 700 | 1000 | 1500 |

| Drying blower | Kw | 0.4 | 0.75 | 1.1 | 1.5 | 2.2 | 3.75 | 5.5 | 7.5 | 7.5 | 7.5 | 11 |

| Regen. blower | Kw | 0.2 | 0.2 | 0.2 | 0.2 | 0.4 | 0.75 | 0.75 | 1.5 | 2.2 | 3.0 | 3.8 |

| Regen. heater | Kw | 2.4 | 3.6 | 3.6 | 3.6 | 5.4 | 7.2 | 7.2 | 10 | 12 | 12 | 20 |

| Inlet/Outlet Pipe Dia | Inch | 2″ | 2″ | 2″ | 2″ | 2.5″ | 3″ | 3″ | 4″ | 5″ | 5″ | 6″ |

| Voltage | V |

| ||||||||||

| W | Mm | 500 | 600 | 600 | 600 | 800 | 800 | 950 | 950 | 1280 | 1280 | 1350 |

| D | Mm | 650 | 800 | 800 | 800 | 900 | 900 | 1050 | 1050 | 1380 | 1380 | 1450 |

| H | Mm | 1100 | 1300 | 1300 | 1400 | 1550 | 1550 | 1700 | 1700 | 2200 | 2200 | 2300 |

| Weight | Kg | 150 | 215 | 265 | 272 | 392 | 405 | 575 | 650 | 880 | 880 | 950 |

The specification is subject to change without prior notice.

Specifications of the Drying Capacity

| Material | Drying temp | Drying time | Specific Heat | Specific Gravity | Before drying | After drying | Drying Capacity | ||||||||||||||

| ND-30 | 50 | 80 | 120 | 150 | 200 | 300 | 400 | 500 | 700 | 1000 | 1500 | 2000 | 3000 | 4000 | |||||||

| ABS | 80 | 2-3 | 0.34 | 0.6 | 0.3 | 0.02 | 11 | 18 | 27 | 35 | 71 | 200 | 180 | 210 | 285 | 355 | 425 | 710 | 1065 | 1500 | 1600 |

| CA | 75 | 2-3 | 0.5 | 0.5 | 1 | 0.02 | 9 | 15 | 22 | 30 | 60 | 105 | 150 | 180 | 235 | 295 | 355 | 590 | 885 | 1200 | 1330 |

| CAB | 75 | 2-3 | 0.5 | 0.5 | 0.8 | 0.02 | 9 | 15 | 22 | 30 | 60 | 90 | 150 | 180 | 235 | 295 | 355 | 590 | 885 | 1200 | 1330 |

| CP | 75 | 2-3 | 0.6 | 0.6 | 1 | 0.02 | 11 | 18 | 27 | 35 | 71 | 90 | 180 | 210 | 235 | 355 | 425 | 710 | 1060 | 1500 | 1600 |

| LCP | 150 | 4 | 0.6 | 0.6 | 0.04 | 0.02 | 8 | 13 | 20 | 27 | 55 | 106 | 135 | 160 | 210 | 265 | 320 | 530 | 800 | 1150 | 1200 |

| POM | 100 | 2 | 0.35 | 0.6 | 0.2 | 0.02 | 16 | 27 | 40 | 53 | 105 | 80 | 265 | 320 | 425 | 530 | 640 | 1060 | 1600 | 1800 | 2400 |

| IONOMER | 90 | 3-4 | 0.55 | 0.5 | 0.1 | 0.04 | 7 | 11 | 17 | 22 | 44 | 160 | 111 | 133 | 177 | 220 | 265 | 442 | 663 | 750 | 1000 |

| PA6/6.6/6.10 | 75 | 4-6 | 0.4 | 0.65 | 1 | 0.05 | 6 | 10 | 14 | 19 | 38 | 66 | 96 | 115 | 153 | 192 | 230 | 383 | 575 | 960 | 1040 |

| PA11 | 75 | 4-5 | 0.58 | 0.65 | 1 | 0.05 | 7 | 12 | 17 | 23 | 46 | 58 | 115 | 138 | 184 | 230 | 275 | 460 | 690 | 780 | 1150 |

| PA12 | 75 | 4-5 | 0.28 | 0.65 | 1 | 0.05 | 7 | 12 | 17 | 23 | 46 | 69 | 115 | 138 | 184 | 230 | 275 | 460 | 690 | 780 | 1150 |

| PC | 120 | 2-3 | 0.28 | 0.7 | 0.3 | 0.01 | 13 | 21 | 31 | 41 | 83 | 69 | 206 | 250 | 330 | 413 | 495 | 826 | 1238 | 1400 | 1860 |

| PU | 90 | 2-3 | 0.45 | 0.65 | 0.3 | 0.02 | 11 | 19 | 29 | 38 | 77 | 124 | 190 | 230 | 307 | 383 | 460 | 767 | 1150 | 1530 | 2080 |

| PBT | 130 | 3-4 | 0.3-0.5 | 0.7 | 0.2 | 0.02 | 9 | 15 | 23 | 31 | 62 | 115 | 155 | 186 | 248 | 310 | 372 | 620 | 930 | 1100 | 1600 |

| PE | 90 | 1 | 0.55 | 0.6 | 0.01 | <0.01 | 32 | 53 | 80 | 106 | 212 | 93 | 531 | 637 | 850 | 1065 | 1275 | 2125 | 3185 | 3600 | 4800 |

| PEI | 150 | 3-4 | 0.6 | 0.6 | 0.25 | 0.02 | 8 | 13 | 20 | 27 | 53 | 318 | 133 | 160 | 212 | 265 | 320 | 530 | 800 | 1030 | 1370 |

| PET | 160 | 4-6 | 0.3-0.5 | 0.85 | 0.2 | 0.05 | 8 | 13 | 19 | 25 | 50 | 80 | 125 | 150 | 200 | 250 | 300 | 500 | 750 | 1150 | 1360 |

| PETG | 70 | 3-4 | 0.6 | 0.6 | 0.5 | 0.02 | 8 | 13 | 20 | 27 | 53 | 75 | 133 | 160 | 212 | 265 | 320 | 530 | 800 | 1030 | 1370 |

| PEN | 170 | 5 | 0.85 | 0.85 | 0.1 | 0.05 | 9 | 15 | 23 | 30 | 60 | 90 | 150 | 180 | 240 | 300 | 360 | 600 | 900 | 1150 | 1360 |

| PES | 150 | 4 | 0.7 | 0.7 | 0.8 | 0.02 | 9 | 15 | 23 | 30 | 60 | 90 | 150 | 180 | 240 | 630 | 360 | 600 | 900 | 1050 | 1400 |

| PMMA | 80 | 3 | 0.65 | 0.65 | 0.5 | 0.02 | 11 | 19 | 29 | 38 | 77 | 115 | 190 | 230 | 310 | 385 | 460 | 765 | 1150 | 1530 | 1730 |

| PPO | 110 | 1-2 | 0.4 | 0.5 | 0.1 | 0.04 | 13 | 22 | 33 | 44 | 88 | 133 | 220 | 265 | 355 | 440 | 530 | 885 | 1330 | 1730 | 2660 |

| PPS | 150 | 3-4 | 0.6 | 0.6 | 0.1 | 0.02 | 8 | 13 | 20 | 27 | 53 | 80 | 133 | 160 | 212 | 265 | 320 | 530 | 800 | 1030 | 1370 |

| PU | 120 | 2 | 0.27 | 0.6 | 0.4 | 0.02 | 16 | 27 | 40 | 53 | 105 | 160 | 265 | 320 | 425 | 530 | 640 | 1060 | 1600 | 1800 | 2400 |

| PP | 90 | 1 | 0.46 | 0.5 | 0.1 | 0.02 | 26 | 44 | 66 | 88 | 180 | 265 | 442 | 530 | 710 | 885 | 1060 | 1770 | 2655 | 3500 | 4000 |

| GP(GP) | 80 | 1 | 0.28 | 0.5 | 0.1 | 0.02 | 26 | 44 | 66 | 88 | 180 | 265 | 442 | 531 | 708 | 885 | 1062 | 1770 | 2655 | 3500 | 4000 |

| PSU | 120 | 3-4 | 0.31 | 0.65 | 0.3 | 0.02 | 8 | 14 | 22 | 29 | 60 | 85 | 145 | 173 | 230 | 290 | 345 | 575 | 865 | 1300 | 1485 |

| PVC | 70 | 1-2 | 0.2 | 0.5 | 0.1 | 0.02 | 13 | 22 | 33 | 44 | 90 | 135 | 220 | 265 | 355 | 442 | 530 | 885 | 1330 | 1730 | 2660 |

| PAN(AS) | 80 | 14-2 | 0.32 | 0.5 | 0.1 | 0.05 | 13 | 22 | 33 | 44 | 90 | 135 | 220 | 265 | 355 | 442 | 530 | 885 | 1330 | 1730 | 2660 |

| TPE | 110 | 3 | 0.7 | 0.7 | 0.1 | 0.02 | 13 | 20 | 30 | 40 | 85 | 125 | 205 | 250 | 330 | 413 | 495 | 826 | 1238 | 1650 | 1860 |